Science fiction is no longer the exclusive domain of robotics; it is becoming a major force in technology, transforming a variety of industries. Robots are changing many aspects of our lives—from healthcare to manufacturing, consumer goods to driverless cars. They are changing the way we live, work, and engage with the world. Robotics is pushing the frontier of innovation as machine learning, artificial intelligence (AI), and sensor technology develop. This article looks at the history of robotics, its many uses, and how it will likely influence technology in the future.

The Development of Robotics: A Brief History

The concept of robots has existed for centuries, but the development of modern robotics began in the 20th century. The word “robot” was first introduced by Karel Čapek in his 1920 play R.U.R. (Rossum’s Universal Robots), where it described artificial beings designed for labor. However, robotics as we know it started gaining momentum in the 1950s and 60s, with significant advancements in automation.

One of the early breakthroughs was the creation of Unimate, the world’s first industrial robot, by George Devol and Joseph Engelberger in 1961. Unimate was designed to automate tasks like welding and assembling in General Motors’ factories. It was a game-changer for the automotive industry, making manufacturing faster, more efficient, and safer.

Fast forward to today, robots have evolved to perform more complex tasks. Modern robots are used across industries for precision tasks, and they even interact with humans through advancements in AI and machine learning.

Core Components of Robotics

Robots are built on three fundamental components: sensors, actuators, and control systems. Together, these elements allow robots to perform tasks, interact with their environment, and execute complex operations.

- Sensors: Sensors allow robots to perceive their environment by gathering data. These include cameras, infrared sensors, GPS, accelerometers, and more, enabling robots to detect obstacles, measure distances, and understand their surroundings. In applications like autonomous vehicles, sensors play a crucial role in object detection and navigation.

- Actuators: Actuators are responsible for movement and are considered the muscles of a robot. They include motors, hydraulic systems, and pneumatic systems that allow robots to move limbs, wheels, or other components. Industrial robots, for example, rely on actuators to control robotic arms used in manufacturing processes.

- Control Systems: Control systems serve as the “brain” of the robot, processing the input from sensors and directing the actuators. These systems can vary in complexity, from basic control algorithms to sophisticated AI-driven systems that enable autonomous decision-making. Control systems allow robots to perform tasks efficiently and adapt to dynamic environments.

Industrial Automation: Robotics in Manufacturing

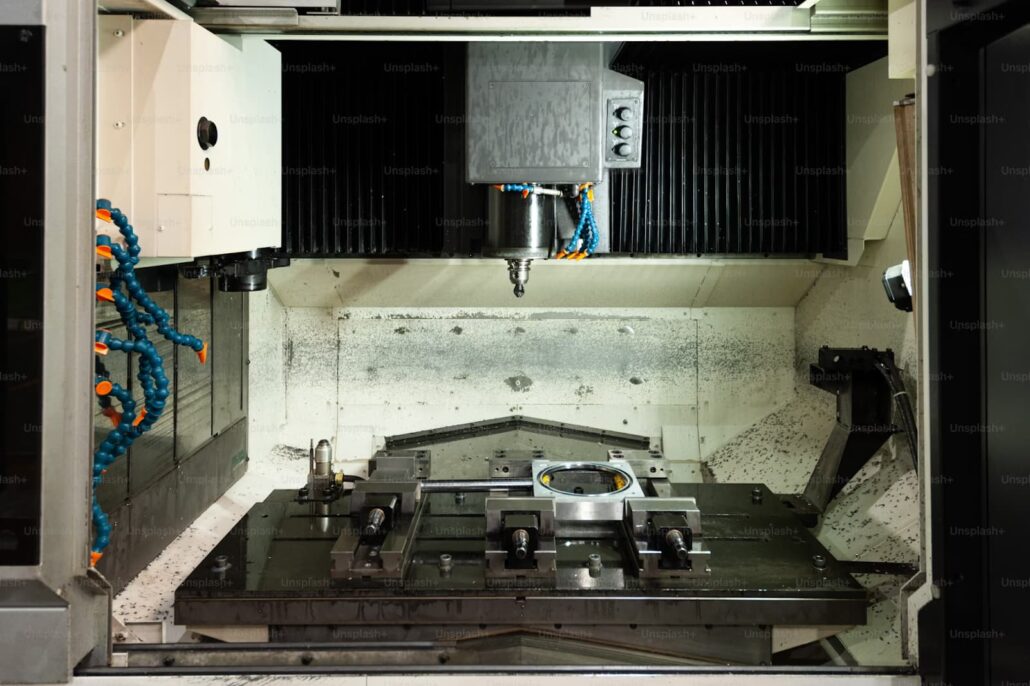

In the field of industrial automation, robotics has become essential, particularly in the manufacturing of consumer items, electronics, and automobiles. These environments are ideal for robots because they do repetitive, precision-based activities well, which minimizes human error, increases production speed, and lowers operating costs.

One of the most prominent examples of robotics in industrial automation is the robotic arm. These arms are equipped with tools, sensors, and precision actuators that allow them to perform tasks like welding, painting, assembling, and packaging. In the automotive industry, for instance, robotic arms are widely used to weld car frames with exceptional accuracy and speed.

In addition to assembly and production tasks, robots are increasingly used for quality control. With advancements in vision systems and AI, robots can inspect products for defects, ensuring higher consistency and quality. This automation not only reduces human error but also decreases waste, making production more efficient.

The rise of “lights-out” manufacturing, or factories that can run without human intervention, is a testament to the future potential of industrial automation. These fully automated factories leverage robotics to operate 24/7, significantly boosting production capacity and reducing labor costs.

Robotics in Healthcare: Enhancing Medical Capabilities

Healthcare has become one of the most promising sectors for robotics, with applications that range from surgery to rehabilitation. Robots are helping doctors, surgeons, and healthcare professionals deliver better care while improving patient outcomes.

Surgical robots are now widely used to assist surgeons during complex procedures. One of the most well-known systems is the Da Vinci Surgical System, which allows surgeons to perform minimally invasive surgeries with enhanced precision and control. With robotic assistance, surgeries are less invasive, leading to quicker recovery times and reduced scarring for patients.

Rehabilitation robots are making a significant impact in helping patients recover from injuries or surgeries. These robots provide personalized rehabilitation exercises, guiding patients through movements and providing real-time feedback. Exoskeleton robots, for example, support patients with limited mobility, allowing them to regain strength and independence.

Care robots are also being developed to assist elderly individuals and those with disabilities in their daily lives. These robots can help with tasks such as medication management, mobility assistance, and monitoring vital signs. As the population continues to age, care robots will likely play an increasingly important role in addressing healthcare needs.

The Role of AI in Auto Robots

AI is revolutionizing robotics by enabling the development of autonomous robots—machines that can operate without human intervention. These robots rely on AI algorithms to make real-time decisions based on sensory data, allowing them to navigate, learn, and adapt to changing environments.

Autonomous vehicles are perhaps the most visible example of this. Companies like Tesla, Waymo, and Uber are developing self-driving cars that use AI-powered systems to analyze data from cameras, radar, and LiDAR sensors. These systems allow the vehicles to recognize obstacles, follow traffic rules, and safely transport passengers. Autonomous driving technology has the potential to reduce traffic accidents, enhance road safety, and change the transportation landscape.

In industries like logistics, autonomous drones and warehouse robots are revolutionizing tasks like package delivery and inventory management. Companies such as Amazon are exploring drone-based delivery systems, while robots are being used in warehouses to automate picking, packing, and transporting goods.

In agriculture, autonomous robots are being deployed for tasks like planting, harvesting, and monitoring crops. These robots can work around the clock, increasing productivity while lowering labor costs. By integrating AI and robotics, farmers can optimize their operations and make data-driven decisions to improve crop yields.

Consumer Robotics: A Growing Market

Robots are also entering the consumer market, making daily tasks easier and more efficient. One of the most common examples is the robot vacuum cleaner, such as the Roomba. These robots navigate homes, detect obstacles, and clean floors autonomously. With advancements in sensor technology and AI, consumer robots are becoming more sophisticated and user-friendly.

Personal assistant robots like Amazon’s Alexa and Google Home provide virtual assistance, controlling smart home devices, answering questions, and managing schedules through voice commands. While these robots may not have physical mobility, they are part of a growing trend of integrating AI into everyday consumer products.

In the future, consumer robots will likely expand into more advanced roles, offering services such as cooking, cleaning, and even providing companionship. As technology improves, robots are expected to become a staple in households, providing convenience and improving quality of life.

Conclusion

Robotics has become a critical force across industries, driving innovation and reshaping the future of technology. From industrial automation and healthcare advancements to autonomous vehicles and consumer products, robots are transforming how we live and work. As AI and sensor technology continue to evolve, robots will become even more intelligent, capable, and essential in meeting the demands of a rapidly changing world.